Describe the Uses of Galvanized Iron Sheets

Awnings Balconies Building frames Canopies Ductwork Handrails Fences Industrial walkways Ladders Staircases Street Furniture Support Beams Verandas. One of the prominent advantages of Galvanization is that it helps in the construction and repairing work of steel structures.

What Are The Benefits Of Galvanized Sheet Metal

Therefore there will be decreased danger of injury and reduced maintenance cost.

. Like tinplate early galvanized metals were hand dipped. However the most commonly used ones are still hot dip galvanized sheets. The resulting finish is a dull matte surface.

In construction activities GI sheets find wide use as roof sheets walls panels covers rolling shutters highway bombers partition walls and painted coated products. In the galvanized steel industry gauge is a term used to describe the materials density in pounds per square foot or pounds per square inch PSF. Although uncertain the first use of galvanized corrugated iron is believed to be for the Navy at Pembroke Docks Wales in 1844.

The corrugations will increase the strength of steel sheet. The construction and automotive industries use galvanized steel for machine parts and tools. The hot-dip method involves the deposition of zinc onto the surface of iron by dipping the iron is molten hot zinc.

Both galvanized iron and steel are magnetic pure zinc is not. In addition to the hot-dip method theres also the cold galvanization. Both of these methods employed a hot dipping process to coat sheet iron with zinc.

However galvanized sheet metal-specific uses include. The sheets are available in thickness of 063 mm to 160 mm. GI sheets find uses in every sector of the economy.

Door and window hoods. Galvanized iron sheets are an essential part of our lives as they are used in construction transport and any other sectors where preventing corrosion is a vital factor. However galvanized sheet metal-specific uses include.

With 050mm thick galvanized steel a gauge of 22 is equivalent to a 20-gauge galvanized steel. Lots of household items are made with GI sheets. By 1850 the British galvanizing industry was using 10000 tonnes of zinc a year for the protection of iron.

These are commonly available in length of 25 meter having a width of 900 mm and 1000 mm. Galvanized sheet metal offers its uses on phone wiring and equipment boxes. The longevity of galvanized sheet steel easily makes it the most efficient construction material to use.

They are used in agriculture as grain silos feeding troughs sprayers and pans. But each metal has its specific uses. These sheets are coated with zinc.

Its the most common method used to create galvanized iron. Galvanized steel sheets can be further divided into galvanized steel sheets for general use roofing exterior panels for buildings structural tiled slabs tensile and deep drawing. Cost-Effective Galvanized Steel.

Typical uses today include. Buckets tubs and other containers. Most are galvanized to prevent rust and corrosion.

Cornices and other wall ornaments. Sheet steel that is galvanized improves usability allowing users to spend less. There are several methods used to create galvanized iron one of which is the hop-dip method.

This is why companies such as Harwal Group the best building materials manufacturers make this kind of material which can be acquired in this link. Most of the time too galvanized sheets are cheaper in the market compared to sheets that underwent other forms of treatment. Generally the most common use for sheet metal is for commercial construction projects.

CGI roofing sheet is short for corrugated galvanized iron roofing sheet which is a kind of cost-effective building material. Typical historical uses for galvanized iron and steel included. Industrial unfinished tough resilient durable.

The use of the coating within the built environment has a long history and its recent popularity as a finish for facade panels especially in Germany and Scandinavia is testament to its inherent characteristics and benefits. The galvanizing process is widely used for providing a coating of zinc on iron and steel. Corrugated Galvanized Iron or steel CGI sheets are used for general roofing purposes.

Hot-Dip Galvanized steel sheet manufacturing process is to clean the iron through the wettability of flux immersed in the zinc bath so that steel and molten zinc reaction to generate a alloy of the skin membrane. Some types come in large rolls or flat sheets that can be cut to size. Galvanization is the process in which there is an application of protective zinc coating to iron or steel that helps prevent premature corrosion and rust.

Galvanized sheet is coated with zinc on the steel plate. Decorative formed shingles and pantiles designed to imitate other materials. The process of galvanizing sheet iron was developed simultaneously in France and England in 1837.

Today almost all galvanized iron and steel is electroplated. It is very much low cost process and widely used for corrosion resistant coating on sheet metal household items for daily used made from iron and steel eg. Chromated surfaces provide an attractive finish that adds a shiny luster to the metal.

Galvanizing steel is a cheaper process than making stainless steel. For roofing purposes the sheets are waterproofing. Stainless steel has a wide variety of grades each with varying amounts of alloys.

Galvannealed steel is conducive to welding and the surface is excellent for paint adhesion. Roof ornaments such as crestings and finials. Electric Equipment and Appliances.

Galvanized and stainless steel both prevent oxidation. It uses galvanized steel sheet as material and then profiles them into corrugated patterns with a roller mill. EN 10160-3 galvanized steel sheet for roofing material 050 mm thick 10503120 mm.

Just some of the adjectives that have been used to describe hot dip galvanizing. Generally corrugated galvanized iron sheets are extensively adopted as a covering for roofs and sides of industrial sheds and buildings. Galvannealed steel is a zinc-iron alloy product where the base metal is coated by the hot-dip process then heated to induce alloying between the molten zinc coating and the steel.

Gi Sheet Definitions Classifications And Uses By Camel Steel Medium

China Galvanized Steel Roofing Sinusoidal Profile Steel Sheet China Roofing Sheet Steel Plate

What Is Galvanized Steel Types Uses Benefits Engineering Choice

Uses Of Galvanized Steel Science Struck

Advantages Of Galvanized Iron Regan Industrial Blog

How Galvanized Sheet Metal Is Used For Everyday Projects

What Are The Classifications And Uses Of Galvanized Steel Sheets

Galvanized Iron Sheets The Advantages Of Using It Abc Money

13 3 0 7 Thick Galvanised Corrugated Roofing Sheets Cladco

Galvanized Corrugated Roofing Sheets Ensure No Surface Rusting

Everything You Need To Know About Galvanized Metal

What Are The Classifications And Uses Of Galvanized Steel Sheets

What Are The Classifications And Uses Of Galvanized Steel Sheets

What Are The Different Applications Of Galvanized Sheet Metals

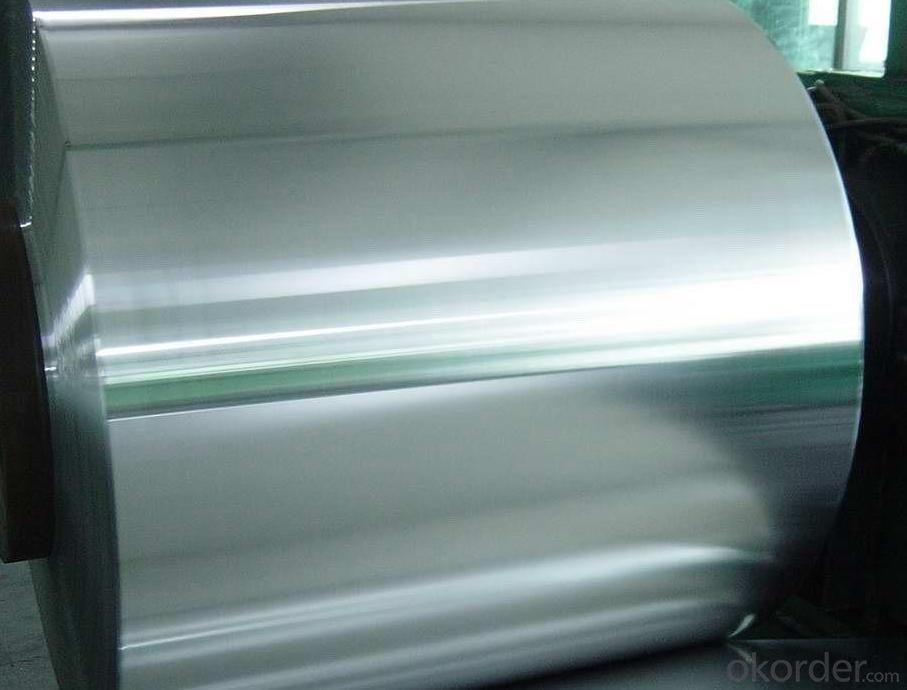

Galvanized Iron Sheet Products Galvanized Iron Sheet Products Galvanized Iron Sheet Suppliers Manufacturers Exporters Okord

G30 Gi Corrugated Iron Metal Roofing Sheet Manufacturers Suppliers Factory Best Price G30 Gi Corrugated Iron Metal Roofing Sheet For Sale Jianhui

The Advantages Of Galvanized Sheet Steel Crown Round Table

China Galvanized Steel Types Of Roofing Iron Sheets In Kenya China Iron Sheet Roofing Kenya Iron Roofing Sheet

Comments

Post a Comment